Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

[]

Model No.: CM-076

MOQ: 1 Pieces

Material: Aluminium

Sample Lead Time: 3 Days

Unit Price: According To Your Products

Surface Treatment: NA

Packaging: According to products

Productivity: 4600/Month

Transportation: Air

Port: Hong Kong

Payment Type: L/C,T/T

Incoterm: FOB

[]

The advantages of CNC Machining are as follows:

1.Reducing the number of tooling. CNC Machining technology can machining complex parts without complex tooling;

2.Stable machining quality of CNC machining products, high machining accuracy, high repetition accuracy, and meet the machining requirements of aircraft CNC machining products;

3.Higher production efficiency in small batch production;

CNC machining technology can machining complex profiles which are difficult to be machined by conventional methods, and even some parts which can not be observed. In summary, CNC machining products are the kind of precise parts that are more complex in structure and small in quantity, such as precision axle, optical fiber tail handle, pin and so on.

Our factory provide CNC machining service for custom CNC Machining Parts, turning parts, springs, cold forming parts, screw machined parts. We can produce CNC machined parts according to your requirements.

CNC Machined parts include: Hydraulic, valve, flange, automobile, shaft, bearing housing bar, plate,welded part, marine part, winch part, sheet metal

CNC Milling Materials: Aluminum 6061, 6063, 6061-T6, 7075, 5052, 2017, 6082. Steel: Q235, 45#, A3, 718H, S136, SKD11. Stainless steel: SUS303, SUS304,( 57310628, 57273318, 57271601, 57242800, 57167502, 57157481, 57153047, 57150572, 56726168, 56719311, 56712752, 56532120, 56393431, 55840789,1.4301), SUS316. Brass/ copper / bronze. Plastic: PEI (Ultem), POM, Teflon, PA,( 57310629, 57273319, 57271602, 57242801, 57167503, 57157482, 57153048, 57150573, 56726169, 56719312, 56712753, 56532121, 56393432, 55840790, PA66 ) PC, PMMA (Acrylic), PEEK, Nylon etc..

Equipment: Common lathe, CNC Machine, Milling, Turning, Spring Machine

Metal Process: CNC Turning, CNC milling, cutting, drilling, planning, grinding, welding.

Surface Treatment: anodize (clear, black, blue, yellow, can also customize a variety of colors), sandblasting, spraying, passivation, laser engraving LOGO, silk screen LOGO, Zn plated, Cr /Ni plated, hot-dip galvanizing, paint, powder coating, brush, polish.

Files of drawings: CNC Machining can import your PDF, CAD, IGES, STEP, STP, X-T files. Please send us your drawings for a quote. We will reply you as soon as possible.

Technical: Dedicated mechanical designer, experienced worker 3D design service inclusive of modeling, analysis and detailed drawing at normal cost. We have a professional team of CNC machining technology, accumulated a lot of experience in machining .Our technical team will review each drawing and arrange each machining step, set the parameters of the CNC machining center. We also have set up a special sample production team to provide small quantities of machining services.

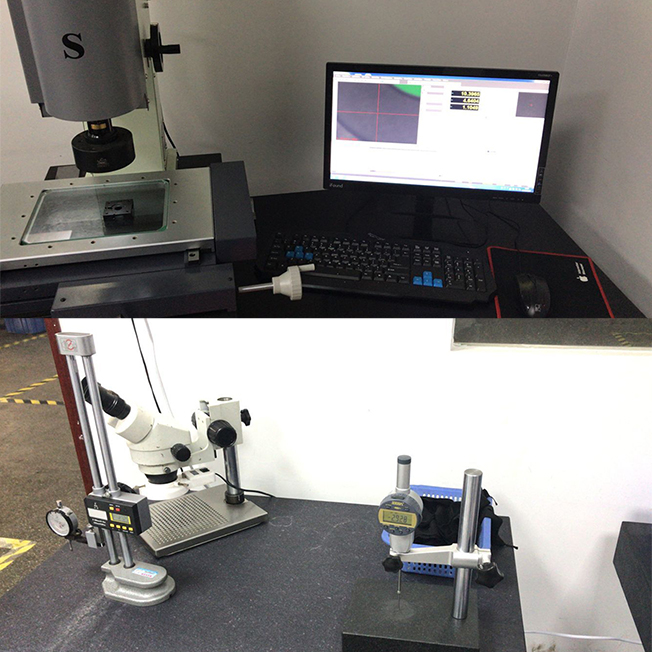

Quality: Pass ISO 9001: 2008. We use ISO9001:2008 quality system certification to ensure the quality of products. Quality personnel are measuring the size of each piece of machining products, measuring instruments include Digital caliper, Micrometer Calipers, height gauge, Profile projecto, these measuring instruments regularly through the third party laboratory calibration, the measurement accuracy is 0.001mm. In order to improve the speed of the inspection, the engineer designed a precise auxiliary inspection fixture. We can provide the dimensional measurement report of Machining Parts.

Delivery: Fast delivery is our advantage. We can finish the sample of turning parts in 3 days. If you need, we can finish sample machining in one day, and also provide emergency machining service. Our factory offers 2~3 CNC Turning Center, which is specially used for machining samples. The workers in our factory are divided into two groups to ensure that the machine is producing the product for 24 hours.

Packing: According to the products' requirements

If you want to know more about precision CNC machining service, Please contact us.

Product Categories : CNC Milling Machining

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.