Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

[]

Model No.: CU001

Material: Brass

Tolerance: 0.02mm

Sample Lead Time: 3 Days

Finish: NA

Product Size(mm): ф52*86

Productivity: 10400/Month

Transportation: Ocean,Land,Air

[]

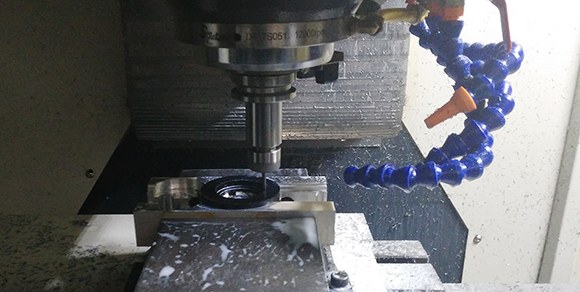

Our technical team has very good experience in Machining Brass,Brass Machined Parts including brass plate, brass rod, brass tube.The binary alloys of copper and zinc are often referred to as "yellow copper"Common models are C26000, C27000, C28000, C33000.High-speed milling Machining of brass can get excellent surface finish,Brass after CNC Machining have good strength and wear resistance.

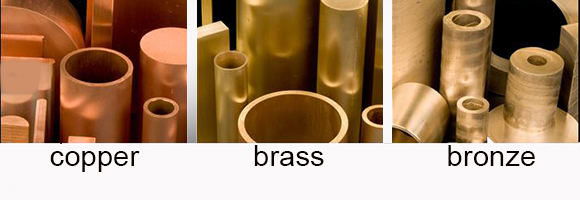

We have three types of Machining Copper:copper, brass, bronze.Copper density of 8.96g / cm3, with excellent electrical conductivity, thermal conductivity, ductility.Using its excellent electrical conductivity and thermal conductivity, machining copper parts are mainly used for generators, wires, switchgear, transformers and other electrical equipment.It is noteworthy that copper will appear sticky knife phenomenon in the machining processing. Brass is added in the copper 25% to 40% Zn and other elements.So the hardness of brass than red copper, but the conductivity is worse than the red copper.Brass high hardness, good wear resistance and corrosion resistance.And has a good mechanical cutting performance.High-speed milling machining of brass can get excellent surface finish,Machining brass pieces are widely used: valves and pipes, radiators, marine parts.Bronze: bronze based on brass joined the Sn, Al, Mn. More abrasion resistance than brass.Bronze in the atmosphere, sea water, fresh water and steam corrosion resistance than brass.Bronze has excellent casting properties, friction reduction performance and mechanical properties.High-speed milling machining of bronze can get excellent surface finish,Machining bronze parts for manufacturing bearings, worm gear, gears.

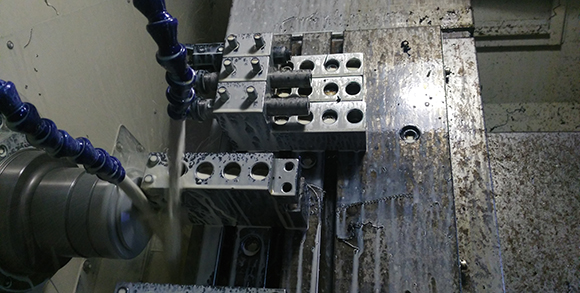

Buildre Group Co., Ltd is a professional manufacturer of CNC and CNC Machining Services and Molding Services for OEM and ODM parts. And through the ISO 9001: 2008 quality certification system, the production base is located in Shenzhen bright. CNC machining plant covers an area of over 2,600 square meters, the main production of CNC Machining Parts for medical, automotive, communications, electrical, electronics and other industries. Production types include CNC Milling,CNC Turning, grinding, stamping, bending, welding, die casting, drilling, tapping and injection molding. More than 46 CNC machining centers and CNC lathes for your service.

Have a professional team of CNC machining technology, accumulated a lot of experience in machining .Our technical team will review each machined drawing and arrange each processing step,Arrange every step of the process, the CNC machining center set parameters.To provide small quantities of machining services, set up a special sample production team.

CNC Machining can import your Para-Solid 3D image files, .PDF and IGES,STEP or SOLIDWORKS files. Please send in your 3d work and PDF for a quote.

Product Categories : Machining Brass

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.